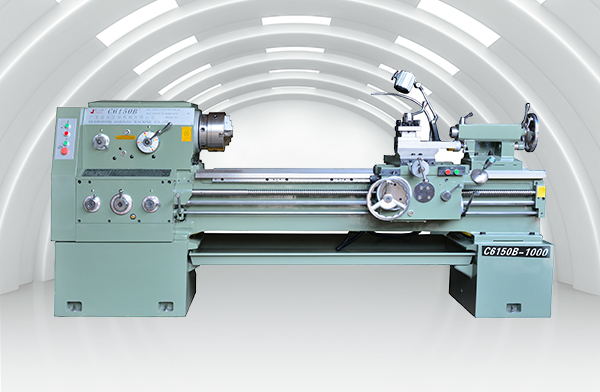

¡ö Machine Introduction

C61 (2) 50B series ordinary horizontal lathes are mainly used for the processing of outer circles, inner holes, end faces, tapers, grooves, and metric, inch, module, and diametral pitch threads of various rotating parts. They are highly versatile horizontal lathes. Featuring high accuracy, high power, strong rigidity, and full functionality, its main structure and components have been optimized and designed, making it the preferred equipment for machining shaft, disk, screw, and special-shaped surface workpieces.

¡ö Technology parameter

| Lathe model | C6150B/1000 | |

| main specifications | Center height | 250mm |

| Maximum turning diameter of bed | 500mm | |

| working length | 1000mm | |

| Tool post maximum travel (longitudinal) | 905mm | |

| The maximum workpiece rotation diameter on the tool post | 300mm | |

| Bar diameter | 80mm | |

| Spindle | Hole diameter | 82mm |

| Cone hole | 1:20/D=90mm | |

| Rotating speed50Hz | 9¡«1600r/min24 levels | |

| knife holder | Tool holder transverse maximum stroke | 340mm |

| Maximum stroke of small knife holder | 145mm | |

| Vertical scale value | 1mm/grid300mm/r | |

| Scale value of horizontal knife holder | 0.05mm/grid5mm/r | |

| Scale value of small knife holder | 0.05mm/grid5mm/r | |

| Turret rotation angle range | ¡À90¡ã1¡ã/div | |

| Distance from spindle centerline to tool support surface | 28mm | |

| Arbor section size(highxWidth) | 25mm¡Á25mm | |

| Longitudinal feed | 0.028¡«6.43mm/r93 types | |

| Infeed | 0.012¡«2.73mm/r93 types | |

| Tailstock | Center hole taper | MT5 |

| The maximum movement of the top sleeve | 150mm | |

| Maximum lateral movement | ¡À15mm | |

| thread | Metric system | 0.55¡«224 mm48 kinds |

| imperial | 72¡«1/8 n/1"48 kinds | |

| modulus | 0.5¡«112mm42 types | |

| diameter pitch | 56¡«1/4DP45 kinds | |

| motor | main motor | Y132M-47.5kw |

| Main motor speed50Hz | 1500 r/min | |

| Dimensions length * width * height | Center distance1000mm | 2485mm¡Á1071mm¡Á1315mm |

| net weight | Center distance1000mm | 2200KG |

| belt | Main drive v-belt model specification | B2286 (B91) |

¡ö Features of the machine tool

1. The machining accuracy of this lathe can reach IT7 level, and the machining surface roughness is not greater than Ra2.5.

2. This lathe uses high-quality resin sand cast iron parts, and the guide rails are precision ground after medium frequency quenching. The matching surfaces of each guide rail are manually scraped and polished. The width of the bed guide rail is 390mm, effectively improving the durability and stability of the machine tool.

3. The spindle aperture is ∅ 82, which is suitable for processing large diameter pipe materials.

4. Using a fast moving motor to drive the vertical and horizontal movement of the tool holder saves processing assistance time. The tailstock adopts roller movement to make the tailstock move more quickly and smoothly.

5. The main shaft adopts a three-point support structure, and the gears are precisely ground after high-frequency quenching, making the machine tool characterized by good rigidity and low noise.

6. Before leaving the factory, this lathe shall be inspected in strict accordance with the inspection procedures, and each machine shall undergo actual cutting tests to ensure that the lathe has good accuracy and processing reliability.

¡ö Introduction to main components

1. Bed

The machine tool adopts a flat guide rail bed structure and high-quality resin sand castings, with a guide rail width of 390mm. The guide rail is precisely ground after medium frequency quenching, and the matching surfaces of each guide rail are manually scraped to ensure good wear resistance and accuracy retention of the machine tool.

2. Bedside box

The main shaft adopts a three-point support structure to maintain a high rigidity during processing. The main transmission has a 24-speed adjustment range of 9 to 1600 r/min, which can meet the cutting requirements of various specifications and types of materials. After high-frequency quenching, each gear is precision ground, and each transmission pair and rolling bearing are strongly lubricated by an oil pump, making the machine tool characterized by high speed, low noise, and low temperature rise. The mechanical overload protection device of the headstock can effectively prevent damage to the machine tool when the processing torque is too large.

3. Feed system

The feed box adopts a "three axis sliding" common gear mechanism, with a thread type changing mechanism and a multiplication mechanism, which can process commonly used threads without changing the change gears. Type and adjustment range of feed rate: 93 types of longitudinal thread: 0.028~6.43mm/r, 93 types of transverse thread: 0.012~2.73mm/r, 48 types of metric thread: 0.5~224mm, 48 types of British thread: 72-1/8 t/in, 42 types of modulus thread: 0.5~112mm, 45 types of radial pitch thread: 56~1/4DP. The slide box is equipped with a fast moving motor to drive the tool holder to move rapidly in both the longitudinal and lateral directions. The one-way overrunning clutch of the worm shaft achieves one-way overrunning of the feed input of the hexagonal bar when the fast motor directionally drives the worm shaft. When the knife rest moves longitudinally, the longitudinal moving handwheel of the slide box automatically disengages, and when it stops moving, it automatically switches on, ensuring the safety of the user. When the movement of the tool holder is blocked and the cutting force is excessive, the safety clutch slips to avoid damage to the feed motion chain.

¡ö Machine tool working environment

Ambient temperature: within the range of 5 ¡æ to 40 ¡æ, and the average temperature within 24 hours shall not exceed 35 ¡æ.

Relative humidity: within the range of 30% to 95%, and the principle of humidity change is that it should not cause condensation.

Altitude: below 1000m.

Atmosphere: Free from excessive dust, acid gas, corrosive gases, and salts.

Installation location: Keep away from vibration sources, flammable and explosive materials, and avoid changes in ambient temperature caused by direct sunlight or thermal radiation on the machine tool.

¡ö Standard accessories and special accessories

Standard accessories:

1. Lighting device 2, cooling device 3, three-jaw chuck 4, V-belt

5. Random tools

Special accessories:

1. Four jaw chuck 2, four jaw flange 3, flower plate 4, heel rest 5, center rest